News

Landaal Packaging Systems Acquires Westcott Displays Through Asset Purchase

August 12, 2022

BURTON, MI – February 22, 2021

Landaal Packaging Systems, a third-generation family-owned and operated multi-site corrugated packaging, 3rd party packaging, Point of Purchase display, and full-service design company, has acquired Westcott Displays located in Detroit, MI. Terms of the transaction were not disclosed.

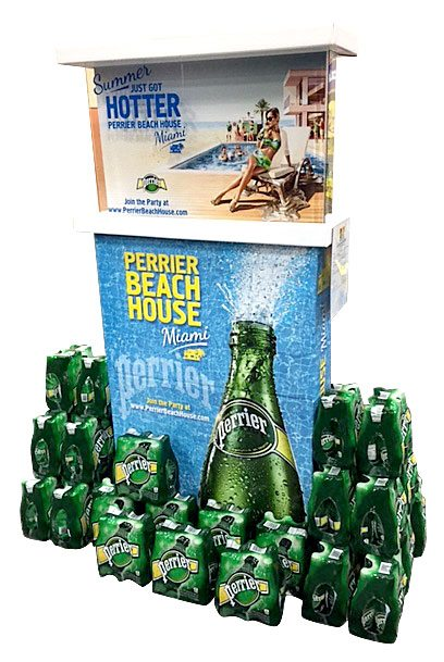

Westcott Displays, one of the country’s oldest and largest manufacturers of Award-Winning Point of Purchase Displays, offers corrugated and folding carton boxes, custom Point of Purchase Displays, and innovative design services. Westcott Displays’ dedication to quality, high-level of customer service, and flexibility align perfectly with Landaal Packaging Systems core businesses and customer service model.

“We are excited that Landaal will be servicing our valued client list,” said Westcott CEO Greg Campbell. “We have worked with them over the past 10 years, so we know from experience that they are an innovative, forward-thinking company with an emphasis on uncompromising customer service.”

Over the past 10 years Landaal Packaging Systems has focused on growing their Point of Purchase Display division, and acquiring Westcott Displays is a cornerstone step into the next evolution of this division’s growth. The acquisition allows for Westcott Displays customers to enjoy the scale of Landaal Packaging Systems national service model, and full range of packaging printing and converting capabilities. “POP display is one of our core businesses, and with the acquisition of Westcott Displays’ assets Landaal is poised for even greater growth in this important segment,” said Robert B. Landaal, company President.

To ensure a smooth transition and seamless client service, Westcott Displays Executive Vice President George Chirillo will join the Landaal team, and said “We will be able to produce our programs more efficiently and be more competitive. I look forward to a smooth transition between the two companies, and providing the high-level of service our Westcott Displays customers expect.”

The Westcott Displays team will continue to service their customers under the Westcott Displays name, and will be integrated into the Landaal Packaging Systems service model. “Westcott Displays customers will now have access to a wider range of value-add services, printing, and finishing capabilities to meet the ever-changing needs for nationwide and regional POP program execution.”, said Mark C. Landaal, Vice President of Sales & Marketing.

ABOUT WESTCOTT DISPLAYS

Westcott Displays is one of the country’s largest and oldest manufacturers and designers of Point of Purchase displays. Since 1920, they have designed and manufactured Point of Purchase Displays and high-graphic Point of Sales items through the spirit of innovation and their nationally recognized excellence in manufacturing processes.

ABOUT LANDAAL PACKAGING SYSTEMS

Landaal Packaging Systems’ mission is to be the best full-service provider of packaging products, supplies and services. Since 1959, they have helped customers solve their packaging problems with innovative ideas, uncompromising product quality and on-time delivery. As a family-owned business, they offer a tradition of consistent, reliable service to companies in the manufacturing, consumer products, and retail industries.

Westcott Displays, Helping Detroit with PPE Face Shield Production

April 21, 2020

Westcott Displays is still hard at work as we mark our 100th year in business this year . As an essential supplier to the food and beverage industry we are still operating but with a new focus. Westcott has been producing PPE face shields for first responders and the medical field across Detroit. Hoping to keep our essential workers on the front-line safer and more comfortable as they work hard keep all of us safe.

We are glad we can help our city and community during this crisis. We would like to thank our employees, customers and suppliers for their dedication and loyalty . Westcott Displays is ready to take on the challenges of the next 100 years together.

Westcott Displays is still hard at work as we mark our 100th year in business this year . As an essential supplier to the food and beverage industry we are still operating but with a new focus. Westcott has been producing PPE face shields for first responders and the medical field across Detroit. Hoping to keep our essential workers on the front-line safer and more comfortable as they work hard keep all of us safe.

We are glad we can help our city and community during this crisis. We would like to thank our employees, customers and suppliers for their dedication and loyalty . Westcott Displays is ready to take on the challenges of the next 100 years together.

Greg Campbell recognized by Printing Industries of Michigan

January 24, 2018

Greg was honored as Printing Industries of Michigan Individual of the Year.

Greg was honored as Printing Industries of Michigan Individual of the Year.

Flat Bed Digital Press Installed

November 2, 2016

Installed in November 2016, Westcott Displays has added a Flat Bed Digital Press to its fleet of printers. With this modern equipment it enables:

With this modern equipment it enables:

- Can print on rigid substrates 65″ wide and up to 2″ thick

- Can print 4 cp plus 2 white channels

- Dynamic curing LED UV lamps

Seize the high-definition imaging opportunity

- Print 4 color plus white on an extended range of flexible and rigid substrates.

- Near-photographic images, saturated colors, and smooth gradations with true 8-level, variable-drop grayscale print capability.

- Industry-leading white ink and single-pass, multilayer printing.

Announcing the installation of the new Versafeeder tipping machine

June 17, 2008

Westcott has enhanced their production capabilities with the addition of a versa-feeder and four pick & place robots. This machine allows full automation to attach, insert and place various items, including:

- Coupon Books

- Business Cards

- Gift Cards

- Credit Cards

- Lug-Ons

- CDs / DVDs

- Take One Pockets

- Easels

- Material Swatches

Westcott Displays announces the installment of it’s full size Automatic Litho Laminator

April 19, 2006

Westcott Displays proudly announces that it has installed a new full size, high speed, automatic single sided mounting machine. The new mounter can run any size sheet up to 64″ x 80″. It can also spot mount as well as mount a full sheet, so it offers new capabilities for Westcott. Westcott has the sheet size capacity to mount and die cut the full size sheets printed on the KBA litho presses that are being installed around the country. This is one more way Westcott is staying on top of the trends in the industry. The new mounter is the fastest and largest litho laminator in the country. This will make us more competitive and save you, the customer, time and money!Westcott Displays announces the installment of two full size die cutting presses

October 26, 2005

Westcott Displays announces the installment of two full size die cutting presses. Both of these presses are larger than any of the other die cutting presses currently on our floor. The largest of the two has a maximum sheet size of 65″ x 80″, and the other press has a maximum sheet size of 55″ x 80″. The current full size press on our floor is 50″ x 80″, so this will increase Westcott’s sheet size capability, and make it compatible with the new large full size litho printing presses being installed around the country. The new additions to our equipment will make us more competitive and better equipped to produce our customer’s programs.